Our Top 10 Warehouse Pallet Racking Accessories - BSE UK

Pallet Racking Accessories Top 10

Pallet Racking Accessories Top 10

A Top 10 Countdown of Accessories for Warehouse Racking

From column guards and safety barriers to weight load signs,take a look the most popular pallet racking accessories are and understand how they can help you and your warehouse become more efficient as well as becoming a safer place to work.

So, here we go. In at number 10….

10. Row Spacers

Pallet Racking Row Spacers fit to the uprights of a double entry rack.

Pallet racking row spacers are occasionally used with double entry racks in order to provide additional strength and rigidity to the system. Racking row spacers are fitted at intervals on back to back uprights and ensure that the rack remains consistent and straight by maintaining the same distance between uprights throughout the entire rack.

9. Rack Labels and Signs

Increase warehouse efficiency by clearly identifying pallet locations with a professional rack labelling system. Clear and concise rack labelling systems really do help to maintain an efficient warehouse facility.

Bespoke racking labels are available and if required, can even be installed by experts on your behalf. Give your forklift truck drivers one less thing to worry about with a clearly identifiable racking system.

Choose from standard codes to barcodes, magnetic labels to vinyl labels – finish your pallet racking system off properly with a professional labelling system.

8. Pallet Support Bars

Pallet Support Bars provide support to weak pallets or extra heavy loads.

Pallet support bars are used as a pallet racking accessory to provide additional support to extra heavy pallet loads, weak and sagging pallets or non standard pallet sizes.

Spanning across the depth of the frame, pallet support bars slot onto existing beams and sit almost flush with the top of the beam. Pallet support bars can also be used to support chipboard decking.

7. Decking for Pallet Racking – Timber, Mesh or Steel Decks

Use decking for non standard pallet sizes and to prevent pallet contamination from falling debris.

If you have a non standard pallet size then you may wish to kit your racking out with decking. Decking enables you to store all pallet types and sizes on a standard warehouse pallet racking system.

Depending on what you are storing and the weight of your pallets, you may require timber, wire mesh or steel decks to enable the safe storage of awkward loads.

6. Anti Collapse Mesh or Netting for Pallet Racking

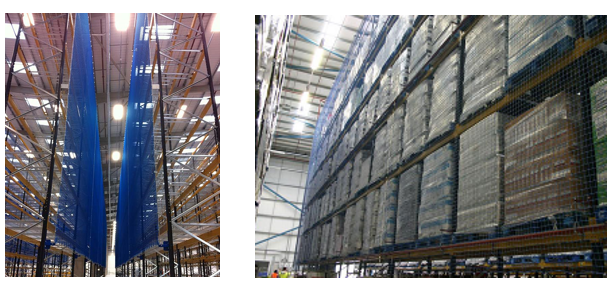

Anti-Collapse Mesh fits onto the back of the rack to provide protection from falling items

Anti-collapse mesh is fitted to the back of single entry racks in order to provide safety and protection from falling objects. Anti-collapse is usually fitted racks with walkways or loading bays to the rear in order to minimise the risk of injury should a pallet or loose items fall from the racking.

Another benefit of anti-collapse mesh is that all pallets remain visible and do not impact on the efficiency and effectiveness of sprinkler systems.

In recent times, a cheaper alternative to anti collapse mesh that is often used is rack netting, which fits to the back of racking and it more flexible and cost effective.

5. Rack Load Signs

Do you know the load capacity of your racking?

A crucial accessory that no pallet racking system should be without is load signs. If you are unaware of the load that your racking can take then you are taking a huge risk. If you’re putting 1 ton pallets up 5 metres in the air then it’s a good idea to make sure your pallet racking is up to the challenge.

Place rack load notices on the ends of each rack so your truck drivers know what load the racking can and can’t handle. (If you’re unsure what load your system can take, have a read through this useful guide to calculating pallet racking weight limits.)

4. Rack End Protection & Safety Barriers

Protect the end frames of your racking from forklift damage using end barriers.

Safety barriers are an increasingly popular pallet racking accessory. End protection barriers are used to protect your racking or storage system from damage at the ends of the aisles. Particularly useful where pallets are pushed up to the racking end frames.

These safety barriers prevent pallets from being pushed up against the racking as well as providing protection from accidental fork lift truck damage.

3. Pallet Racking Column Guards

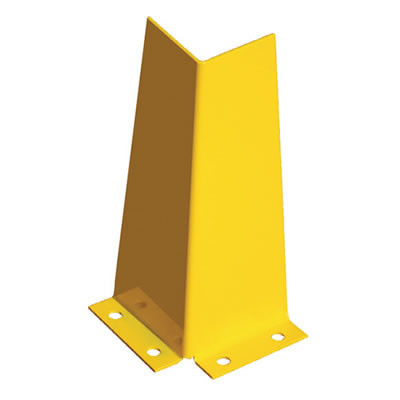

Help prevent damage to your racking uprights by using column guards.

Protect your pallet racking uprights from forklift truck damage using column guards. Column guards are the most common racking accessory and are a cost effective method for limiting damages to the bottom of rack uprights.

It doesn’t take much for a forklift to cause substantial damage to the bottom of racking uprights, which is why businesses across the UK wrap these upright protectors around the base of their storage system.

2. Beam Safety Locks

Underestimated but essential to a safe racking system are beam locking pins.

Pallet racking beam locks or beam clips as they are also known, prevent beams from becoming dislodged accidentally and therefore prevent pallet loads from falling from the racking.

Beams may become damaged or dislodged from the upright by a forklift truck if beam locking clips aren’t in place. Beam safety clips (2 required per beam) are a necessity in any pallet racking system under the guidelines of SEMA and the manufacturers themselves.

1. Pallet Rack Safety Inspection

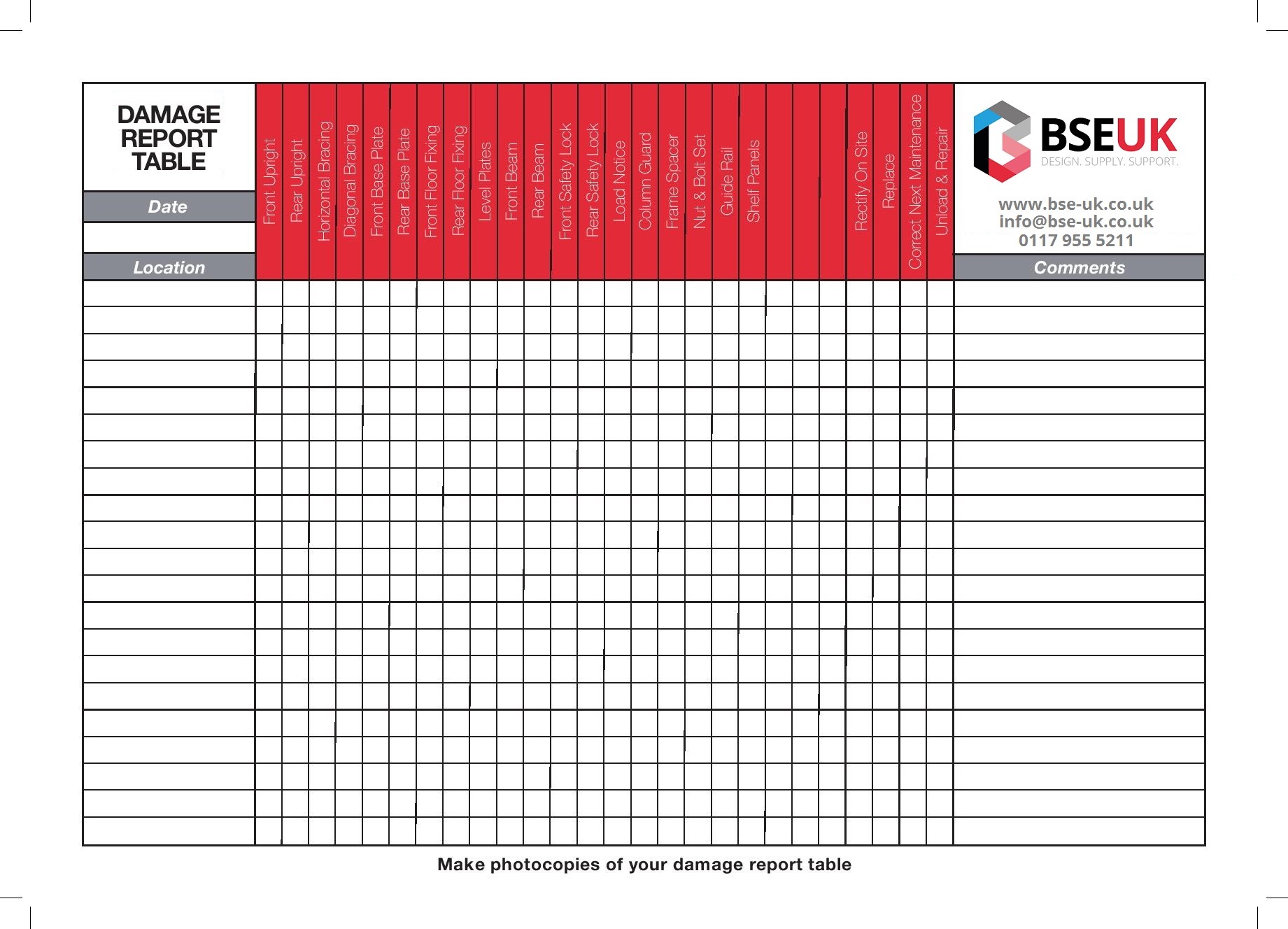

Rack Damage Survey and Inspection Report

Not exactly an ‘accessory’ as such but I can’t omit rack safety inspections from my list! A statutory requirement under Health and Safety Legislation and the PUWER regulation, pallet racking inspections are required to be carried out a minimum of once every year.

All pallet racking inspections must be carried out in accordance with the SEMA guidelines and as well as ensuring safety for your employees, regular rack inspections will help reduce insurance premiums and maintenance costs. Why not book a rack inspection or download our free racking inspection checklist.

Racking Accessories From BSE UK

At BSE UK, we can recommend, supply and fit a wide range of accessories for pallet racking and other storage solutions. Visit our racking accessories page for more information or get in touch with one of the team today.

Contact us

Bristol Storage Equipment Limited

Unit 2, Severnlink Distribution Centre,

Chepstow, NP16 6UN

Sign up to receive our newsletter

By submitting this form you agree to our privacy and data protection policy which governs how we deal with personal data.